Starting from common polymeric materials Cidetec has achieved the goal of getting self-healing elastomers through a simple and inexpensive approach.

WO2015127981A1

“Self-healing elastomer and process for its preparation”

WO2016046135A1

“A self-healing, reprocessable and recyclable crosslinked polymer and process for its preparation”

A particularly useful approach to generate self-healable polymers has been the introduction of reversible or exchangeable bonds into the polymer network.

The idea behind this is to reconnect the chemical crosslinks which are broken when a material fractures, restoring its integrity.

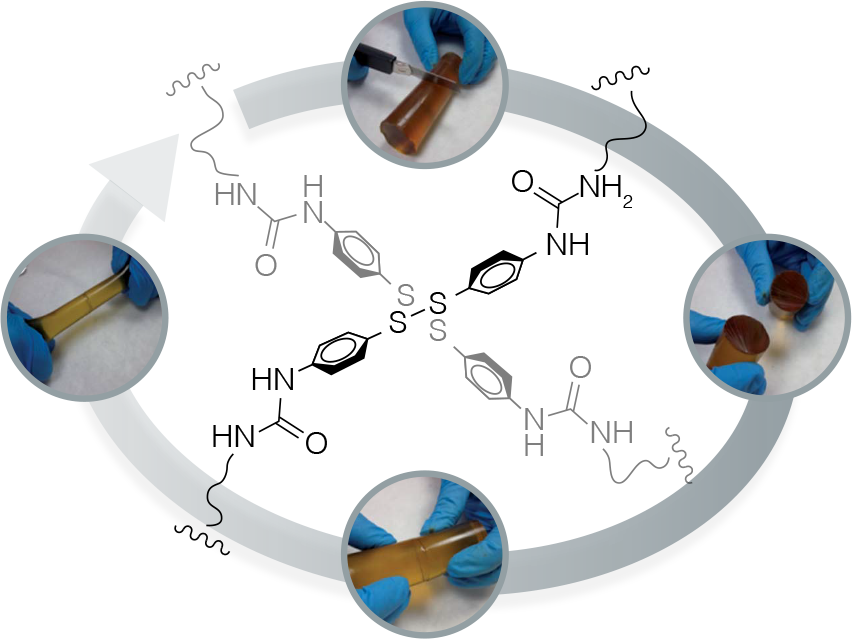

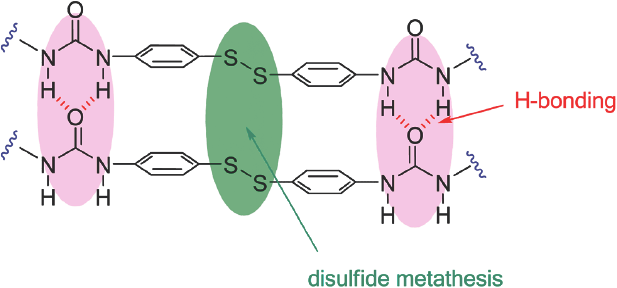

The remarkable self-healing ability of this system could be attributed to two structural features, which are present in this unique crosslinking unit: (i) the aromatic disulfide which is in constant exchange at room temperature and (ii) two urea groups, capable of forming a quadruple H-bond.

The self-healing polymer offer a wide scope of commercial applications thanks to its capacity to improve the security and duration of many plastic parts, for example in cars, houses, electrical components and biomaterials.

The fact that poly(urea-urethane)s with similar composition and properties are already used in many products makes this system very attractive for a fast and easy implementation in real industrial applications.

AUTOMOTION

CONSTRUCTION

ELECTRICAL COMPONENTS

BIOMATERIALS