Designed and synthesized by CIDETEC Surface Engineering, they can be manufactured following traditional methods but the resulting material can be reprocessed, repaired and recycled.

WO2015181054A1

“Thermomechanically reprocessable epoxy composites and processes for their manufacturing”

CIDETEC has developed a new family of enhanced thermoset resins and composites that preserve all the advantages of conventional thermosets while showing unprecedented features such as Re-processability, Reparability and Recyclability (3R technology).

3R epoxy resins and composites are obtained by using dynamic hardeners (commercially available products) which create reversible crosslinks in the polymer matrix.

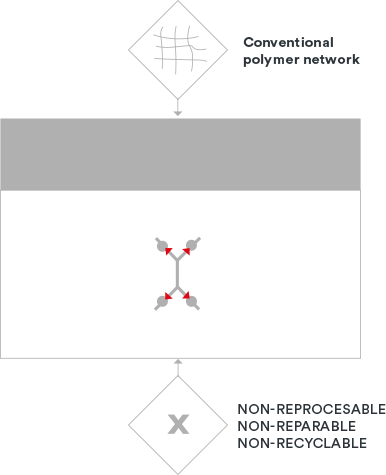

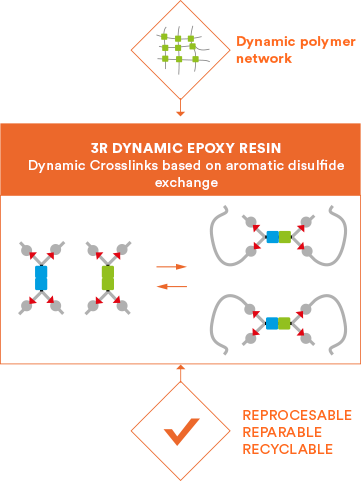

Schematic representation of conventional epoxy vs 3R dynamic resin.

The reshuffling capacity of such reversible crosslinks is responsible of all the smart properties (Re-procesability, Reparability and Recyclability) of the cured 3R composite.

3R laminates can be heated 80oC above the Tg and re-shaped in a few minutes applying pressure, which allows the thermoforming of cured 3R laminates to obtain 3D geometries, in a similar way to thermoplastic composites.

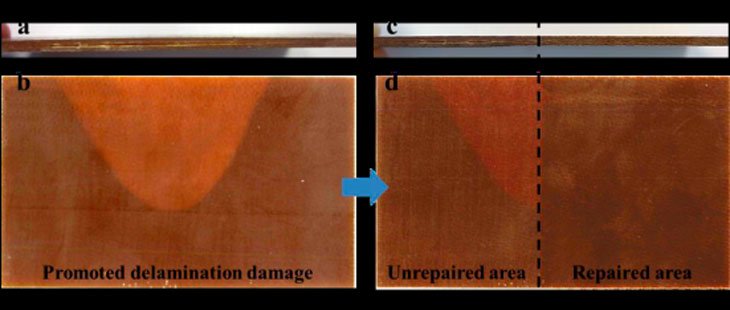

Due to the reshuffling capacity of the dynamic crosslinks, repair of damages based on resin/fibre delaminations and resin micro-cracks are also possible by applying heat and pressure to the damaged part, with a full recovery of the initial properties.

Proof of concept of 3R-Repair: A promoted delamination in a 3R laminate (a & b) was repaired (only half of the damage) by applying heat and pressure (c&d).

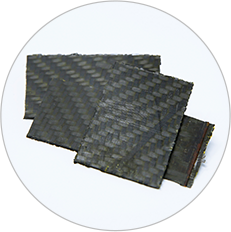

Based on the reshuffling capacity of the dynamic crosslinks, the cured 3R composite can be ground into flakes or pellets which can then be reprocessed by heating 80oC above the Tg and pressing, obtaining a new short fibre reinforced 3R composites.

Proof of concept of mechanical recycling process of 3R-CC scraps

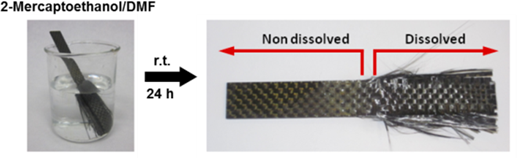

3R epoxy resins can be completely disrupted by the addition of a specific chemical agent. Thus, the resin can be totally dissolved without affecting the reinforcement. In this way, it wil be possible to recover the pristine fibre.

Proof of concept of chemical recycling process of 3R-CC, (a) Matrix dissolution to recover the fibre.

Manufacturing cost savings due to faster and more automated production compared to conventional methods (mainly autoclave).

Reparation of parts delaminated either during the manufacturing process or in service, which currently are rejected due to high cost.

Possibility of recycling the parts at the EoL (not possible with current conventional CCs).

The new FRPCs are easily synthesized from readily available materials and could therefore be implemented in a straightforward manner in transportation, energy or construction industries, among others.

AUTOMOTION

CONSTRUCTION

AEROSPACE

INDUSTRIAL

PROCESSES