Cidetec has developed processes to control surface roughness to measure on a broad range of metal and polymer materials, with different aims such as cleanliness, appearance, activation and/or structuring to facilitate the subsequent application of veneers and/or bonding to dissimilar materials.

The processes of controlling surface roughness to measure developed by Cidetec include mechanical means (sandblasting, vibration), laser, electrochemical procedures (electro-polishing, lightweight alloy anodising) and chemical reactions (chemical attack) as well as combinations of these.

Surface roughness determines many properties for components, such as appearance, ease of cleaning, friction, etc.

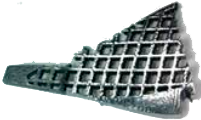

Surface modification by laser treatment, PEO for Ti parts and mechanical treatments for composite CFRP to improve bonding.

Ti6Al4V/CRFP bonding.

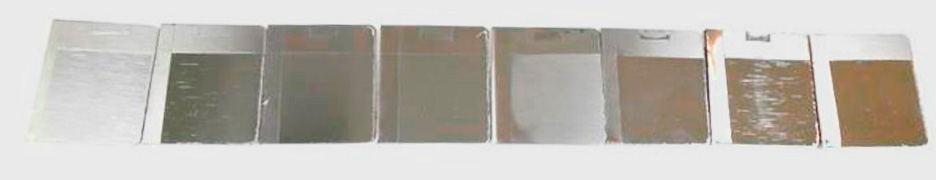

Application of electro-polishing processes to stainless Steel to obtain surfaces of different degrees of brilliance and roughness on Aisi 304 stainless steel..

Stainless steel electro-polished under varying conditions.

The electro-polishing process may be applied to different types of materials and makes it possible to decrease initial roughness by over 60% in relatively short time periods.

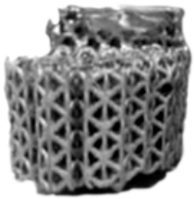

EXAMPLES OF ELECTROPOLISHING DEVELOPMENTS AT CIDETEC

EP components produced by conventional manufacturing processes:

FeNi alloys

Martensitic steel

EP components produced by additive manufacturing processes (3D printing):

Ti alloys

CoCr alloys

Opportunities

Tailored roughness modification processes make it possible to endow the surfaces of treated components with unique properties such as cleanliness, appearance, activation and/or structuring to facilitate the subsequent depositing of veneers and/or the bonding of dissimilar materials. These properties are demanded by many sectors such as motor vehicles, aeronautics, implants, food... hence, the industrial implantation of surface modification processes is highly attractive.