LUBGEAR: Tribological behaviour under loss of LUBrication of new optimized GEARs for friction reduction in power gearboxes

Tribological behaviour under loss of LUBrication of new optimized GEARs for friction reduction in power gearboxes.

This project has received funding from the Clean Sky 2 Joint Undertaking (JU) under grant agreement No 101007713. The JU receives support from the European Union’s Horizon 2020 research and innovation programme and the Clean Sky 2 JU members other than the Union.

Countries: 1 Spain, 3 Austria, 1 Germany

Duration: 34 months

Funding: 1.099.946,25 €

Partners: 5

LUBGEAR aims at demonstrating gear design solutions which can withstand off-design conditions in geared turbofans without additional means (secondary/auxiliary lubrication). Those solutions combine 1) optimized gear geometry providing low power loss conditions; and 2) Surface and material combinations providing low friction. The solutions aim at reducing friction losses and frictional heat, leading to reduced temperatures and risk of scoring. This will allow producing gears which do not face catastrophic damage even under loss of lubrication in off-design conditions.

An investigation of new enabling technologies regarding off-design conditions will be carried out in simulation and experiment at contact level (TRL2). The combination of material systems (roughness, coating and hardening), contact load, sliding speed, rolling speed, lubricant type and lubricant supply will be considered through a Design of Experiments, allowing LUBGEAR to create a unique database and extend contact modelling tools.

Gear Design Optimisation takes into account the results from contact level and derives solutions coming from geometry, material systems, operating conditions and passive lubrication. A demonstration of the most promising design and technology solutions for gears will be validated in an experimental component test rig at TRL3 level. Gear modelling addresses the predictive design of off-design conditions. LUBGEAR project gathers 5 strategic partners based on a multidisciplinary approach combining uniquely engineering, tribology, mechanics, and advanced chemistry.

This will allow developing a gear design with an increase of over 100 % in scoring load and a reduction of over 50 % of frictional losses resulting in remarkable improvements in loss of lubrication conditions. LUBGEAR will assess the benefits of different gear designs including gear geometry, new material systems and passive lubrication technologies in reaching the efficiency and load capacity required for gearboxes.

To reach de goal of further CO2 emission reduction it is necessary to decrease the weight of the engines and to increase the efficiency. Therefore, the goal of LUBGEAR is to develop an optimized gear design which can withstand the off-design conditions without additional means such as secondary or auxiliary lubrication system.

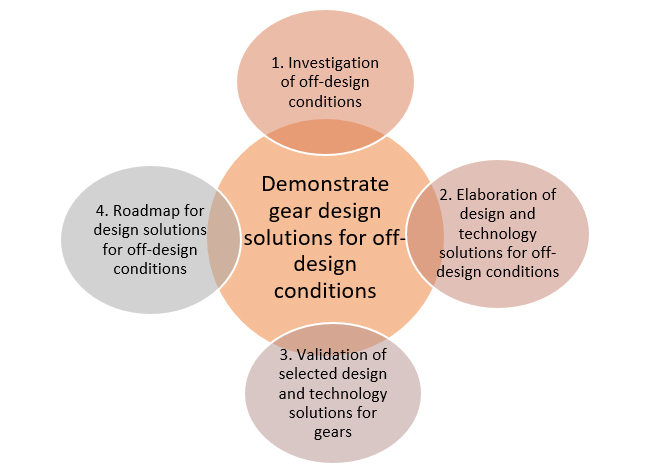

The objective of LUBGEAR is to demonstrate gear design solutions for off-design conditions by means of the following sub-objectives:

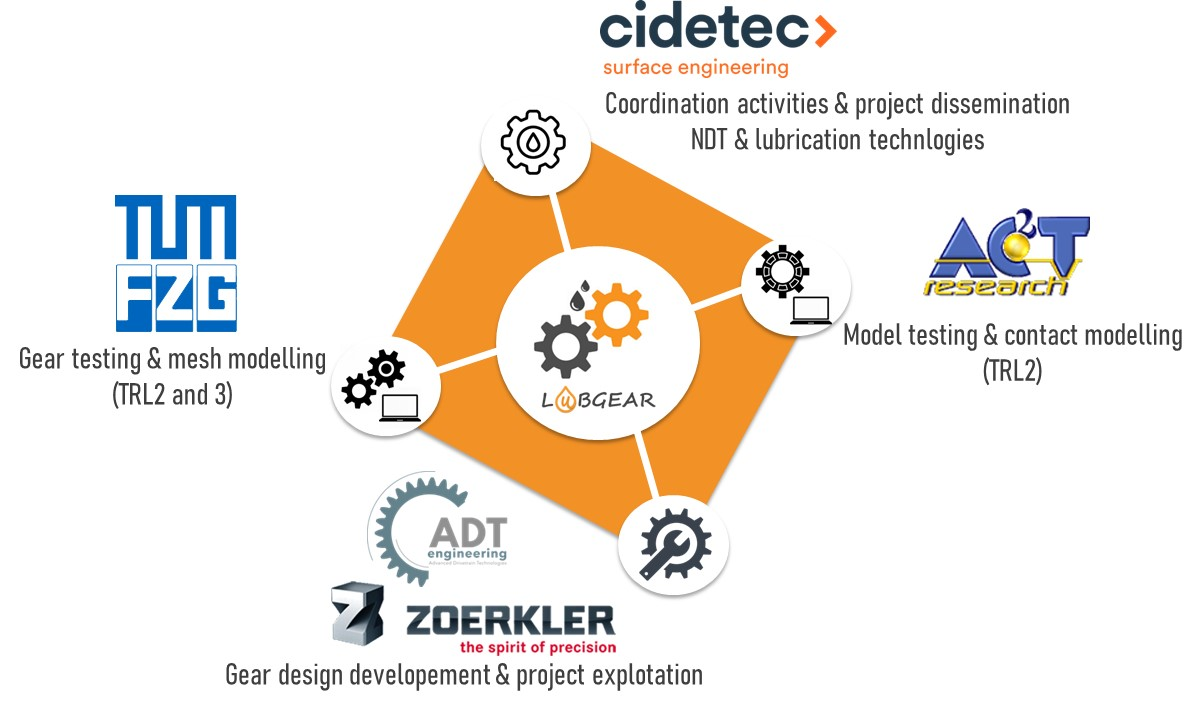

To achieve the proposed challenges, the LUBGEAR project brings together a strong consortium composed of four different partners with complementary profiles and large expertise, covering the special skills, capabilities and certification expected for the project.

This project spearheaded by CIDETEC (Spain), which is a reference centre in Surface Engineering who develops new surfaces with added value (e.g., specific functionalities as self-lubricated surfaces). CID is NADCAP accredited for Non-Destructive-Testing (NDT) and has coordinated two Clean Sky 2 projects. AC2T (Austria) is one of the largest privately held research centre in the world, providing services in the field of tribology and material characterization at a high level, providing high-end technical equipment of the laboratories and expertise of its personnel. ZOERKLER(Austria) is a specialist in the field of aircraft drives. The company brings long-term experience in the development of individual technologies: engine parts for fixed-wing aircrafts, drive systems, and special gear units. And TUM/FZG(Germany) is established today as an internationally renowned research centre for gears and transmissions. The focus of the research activities is the theoretical and experimental development of methods and reliable statements on the service life, efficiency, and noise vibration behaviour of these components. ADT (Austria) is a recently created company specialized in engineering, research and development services around the topic of drivetrains for all modes of mobility.

Avio Aero is the Topic Manager, the private member appointed by the CSJU as responsible for the topic, who will ensure that the project helps to deliver on the objectives of the Advanced Engine & Aircraft Platform and general objectives of Clean Sky2. Avio Aero is a GE Aviation business that designs, manufactures, and maintains components and systems for civil and military aviation.

Dr. Jaime Ochoa Sáenz de la Fuente (Project Coordinator) - CIDETEC

Business Development Manager HEU

email: jochoa@cidetec.es

Dra. Virginia Sáenz de Viteri - CIDETEC

Researcher - Surface Engineering

email: vviteri@cidetec.es